TF-1800

APPLICATIONS

§ Reduce the size shrinkage of the cloth,

§ Prevent the size change and deformation during the production.

§ Enable the cloth cutting goes smoothly.

§ Make lining and shell fabric touch closely. No need to consider shrinkage after cutting, sewing, pressing Much improve the product quality and increase the product value added.

§ This shrinking and forming machine the best choice working with CAD and CAM systems.

FEATURES

§ Independent control for each section conveyor system feeding fabrics with tension free.

§ Wet steam and vibrator system make fabrics be softened completely.

§ The wet fabrics coming from vibrating area will be dried very quickly thru drying area with the appropriate temperature .

§ With powerful cooling system, the temperature of fabrics will be cool down promptly. The fabrics will be formed well due to the temperature difference.

§ Fold the fabrics back and forth with swing structure which will reduce the tension when rewinding.

§ Special auxiliary heating device can make up for the lack of steam heating. The temperature of drying area is fully adjustable.

§ The Meter Counter, equipped as standard, can accurately measure the length of the fabric after forming.

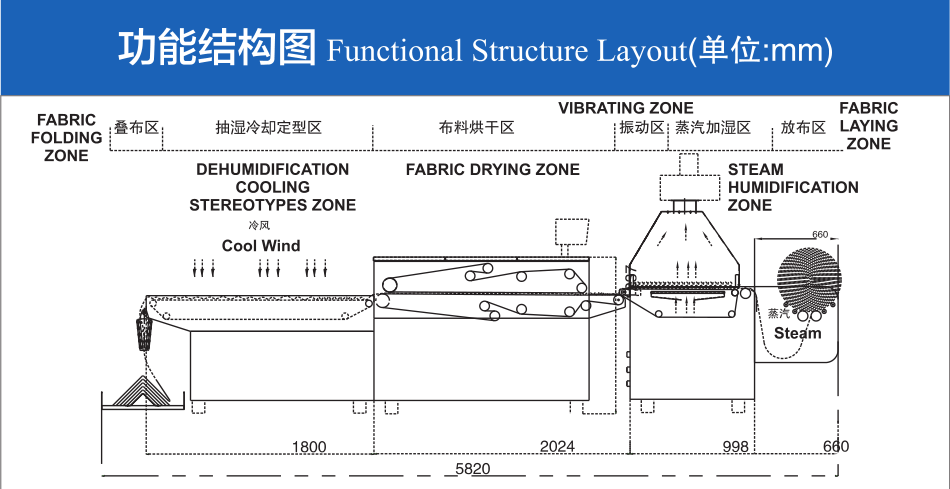

TF-1800 Functional Structure Layout

Specification

|

Model

|

TF-1800

|

| Power supply |

3P220V-380V |

| Air pressure |

0.5-0.7Mpa |

| Steam consumption |

150kg/hr |

| Shrink width |

1800mm |

| Total power |

25KW |

| Cooling motor |

0.75KW*5 |

| Main motor |

0.4KW |

| Conveyor motor |

0.2KW*2 |

| Cloth stand motor |

90W |

| Vibrating moto |

90W |

| Correcting motor |

6W*2 |

| Heating power |

20.4KW |

| Belt speed |

0-10m/min |

| Machine size LxWxH |

5820x2500x2000mm |

| N.W / G.W |

3000/3500kgs |